BY ORDER OF THE

SECRETARY OF THE AIR FORCE

AIR FORCE MANUAL 63-143

18 DECEMBER 2020

Acquisition

CENTRALIZED ASSET MANAGEMENT

PROCEDURES

COMPLIANCE WITH THIS PUBLICATION IS MANDATORY

ACCESSIBILITY: Publications and forms are available on the e-Publishing website at

www.e-publishing.af.mil for downloading or ordering.

RELEASABILITY: There are no releasability restrictions on this publication.

OPR: AFMC/A4F

Supersedes: AFMAN 63-143, 12 August 2015

Certified by: SAF/AQX

(William D. Bailey)

Pages: 96

This Air Force (AF) Manual (AFMAN) implements and identifies Centralized Asset

Management (CAM) procedures referenced in Air Force Instruction (AFI) 63-101/20-101,

Integrated Life Cycle Management. This publication applies to civilian employees and uniformed

members of the Regular Air Force (AF), the United States AF Reserves (USAFR), the Air

National Guard (ANG), and the United States Space Force (USSF), as well as other individuals

and organizations based on binding agreement or obligation with the Department of the Air

Force. Compliance with attachments 2, 3, and 4 in this publication are mandatory. Ensure all

records created as a result of processes prescribed in this publication are maintained in

accordance with AFI 33-322, Records Management and Information Governance Program, and

disposed of in accordance with the Air Force Records Disposition Schedule located in the Air

Force Records Management System. Refer recommended changes and questions about this

publication to the Office of Primary Responsibility (OPR) using AF Form 847, Recommendation

for Change of Publication; route AF Forms 847 from the field through the appropriate chain of

command to the CAM Requirements Branch (AFMC/A4FR) Workflow or AFMC/A4FR, 4375

Chidlaw Road, Room N237, Wright-Patterson Air Force Base, OH 45433-5759. To ensure

standardization, any organization supplementing this manual must send the implementing

publication to SAF/AQX for review and coordination before publishing. The authorities to waive

wing or unit level requirements that are outside of the acquisition execution chain in this

publication are identified with a Tier (“Tier 0, 1, 2, 3”) number following the compliance

statement. See Department of the Air Force Instruction (DAFI) 33-360, Publication and Forms

Management, for a description of the authorities associated with the Tier numbers. Submit

requests for waivers through the chain of command to the appropriate Tier waiver approval

authority, or alternately, to the requestor’s commander for non-tiered, non-acquisition execution

2 AFMAN63-143 18 DECEMBER 2020

compliance items. Mandates to the acquisition execution chain as described in AFI 63-101/20-

101 are not elevated through the organizational chain of authority; therefore tiering in

accordance with DAFI 33-360, is not applied and the waiver authority is as specified. Waivers to

the CAM processes and procedures are reviewed by the applicable program’s Service Core Lead,

coordinated by the branch chief, and the waiver authority is the appropriate Air Force Materiel

Command (AFMC) CAM Chief (AFMC/A4F or AFMC/FMM). The use of the name or mark of

any specific manufacturer, commercial product, commodity, or service in this publication does

not imply endorsement by the AF.

SUMMARY OF CHANGES

This document has been substantially revised and needs to be completely reviewed. Major

changes include reformatted chapters based on CAM processes, expanded language on CAM

governance to include chairs and voting members, updated process flow charts, inclusion of a

roles and responsibilities chapter, inclusion of file maintenance instructions and additional

guidance within each risk category, removal of references to CAFDEx, inclusion of waiver

instruction and tier waiver authority for compliance items, and addition out of cycle guidance,

definitions, and process flow.

Chapter 1—INTRODUCTION 6

1.1. Overview. ................................................................................................................. 6

1.2. Applicability. ........................................................................................................... 6

1.3. Scope. ....................................................................................................................... 6

1.4. CAM Governance. ................................................................................................... 6

1.5. CAM Process and Process Flow. ............................................................................. 7

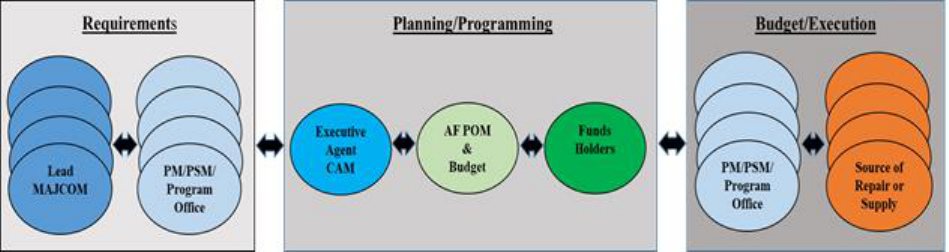

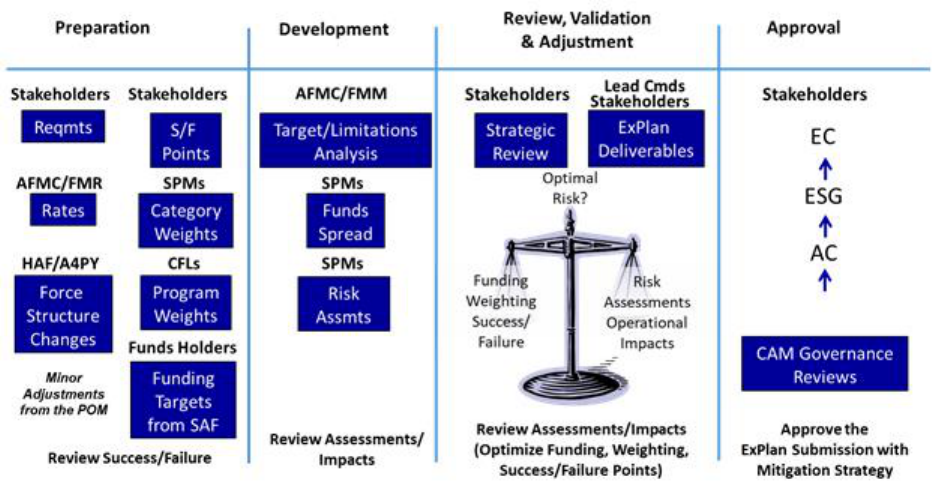

Figure 1.1. The CAM Process. ................................................................................................... 8

1.6. Program Group Entry to Total Force WSS. ............................................................. 9

1.7. Flying Hour Program (FHP). ................................................................................... 9

Chapter 2—ROLES AND RESPONSIBILITIES 10

2.1. Headquarters AF Directorates. ................................................................................. 10

2.2. AF/A3. ..................................................................................................................... 10

2.3. AF/A4. ..................................................................................................................... 10

2.4. Budget Operations Directorate (SAF/FMBO). ........................................................ 10

2.5. Air Force Material Command Commander (AFMC/CC). ....................................... 11

2.6. Working Capital Funds Division (HQ AFMC/FMR). ............................................. 11

2.7. AF CAM Executive Agent....................................................................................... 11

AFMAN63-143 18 DECEMBER 2020 3

2.8. MAJCOM/CCs. ....................................................................................................... 13

2.9. Lead/Supported MAJCOMs. ................................................................................... 13

2.10. Lead Command POC. .............................................................................................. 13

2.11. Supported Commands. ............................................................................................. 13

2.12. Program Executive Officers (PEOs). ....................................................................... 14

2.13. Funds Holder POCs. ................................................................................................ 14

2.14. Program Manager (PM). .......................................................................................... 14

2.15. Chief Engineer. ........................................................................................................ 15

2.16. Engineering Requirements Review (ERR) Manager. .............................................. 15

2.17. Program Office Engineer. ........................................................................................ 16

2.18. Program Office Equipment Specialist (ES). ............................................................ 16

2.19. Program Office Logistics Specialist. ....................................................................... 16

2.20. Maintenance Groups. ............................................................................................... 17

2.21. Work Specification Manager. .................................................................................. 17

2.22. Air Force Sustainment Center (AFSC) 448th Supply Chain Management Wing

(SCMW)................................................................................................................... 17

2.23. Defense Logistics Agency (DLA). .......................................................................... 17

2.24. Depot Maintenance Planner. .................................................................................... 17

Chapter 3—AIRCRAFT AND MISSILE REQUIREMENTS (AMR) PROCESS 18

3.1. Overview. ................................................................................................................. 18

3.2. Supporting Guidance. .............................................................................................. 18

3.3. Aircraft Requirements. ............................................................................................. 19

3.4. Missile Requirements. ............................................................................................. 20

3.5. Depot Schedule and Depot Customer Workload Agreement (DCWA). .................. 21

3.6. Fixed Price Worksheet (FPWS). .............................................................................. 22

3.7. The AMR Process Overview. .................................................................................. 24

3.8. AMR Process: Stage 1 – Define New Tasks and Update Existing Tasks. ............... 25

3.9. AMR Process: Stage 2 – Build and Adjust Hours. .................................................. 26

3.10. Reviews. ................................................................................................................... 27

4 AFMAN63-143 18 DECEMBER 2020

3.11. AMR Brochure. ....................................................................................................... 28

3.12. AMR Process: Stage 3 – PM Certification of Hours. .............................................. 28

3.13. Coordination. ........................................................................................................... 29

3.14. Engineering Requirement Review Process (ERRP). ............................................... 30

3.15. Bill of Work (BOW) Process. .................................................................................. 34

3.16. Maintenance Requirements Supportability Process (MRSP). ................................. 35

Table 3.1. Strategic Supportability – Risk Assessment Criteria. .............................................. 36

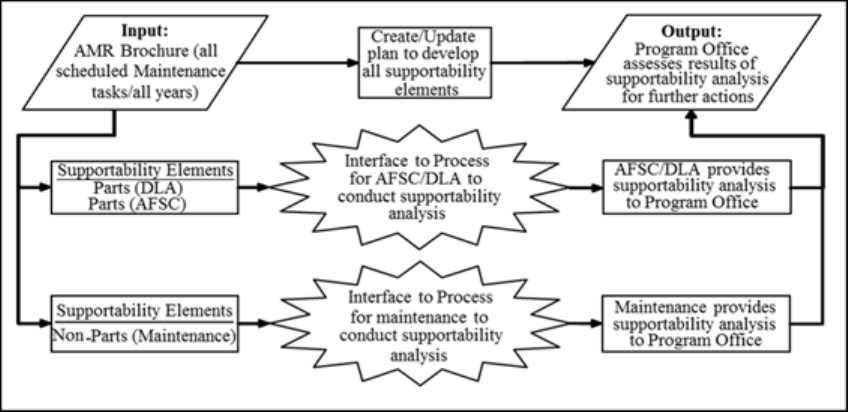

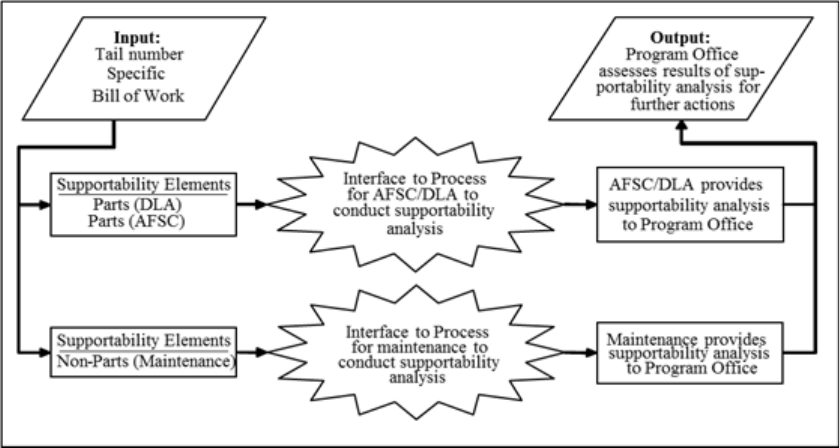

Figure 3.1. Strategic Supportability Assessment Process. ......................................................... 39

Figure 3.2. Published AMR Brochure Supportability Assessment. ........................................... 40

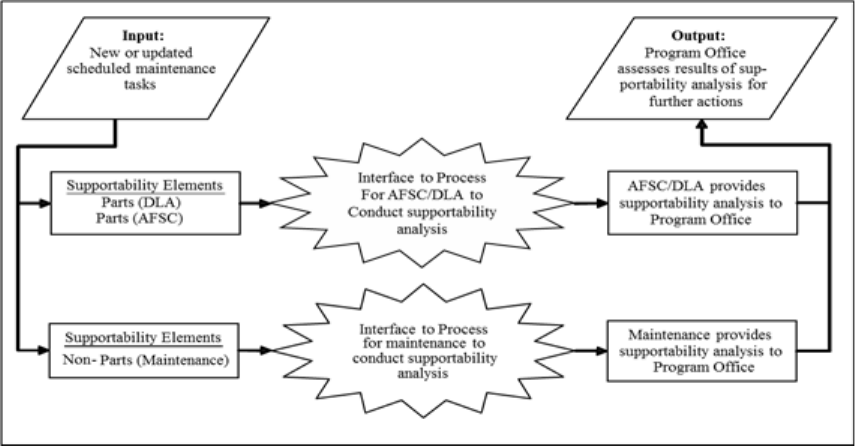

Figure 3.3. Operational Supportability Assessment Process. ..................................................... 43

Chapter 4—LOGISTICS REQUIREMENTS DETERMINATION PROCESS (LRDP) 44

4.1. Overview. ................................................................................................................. 44

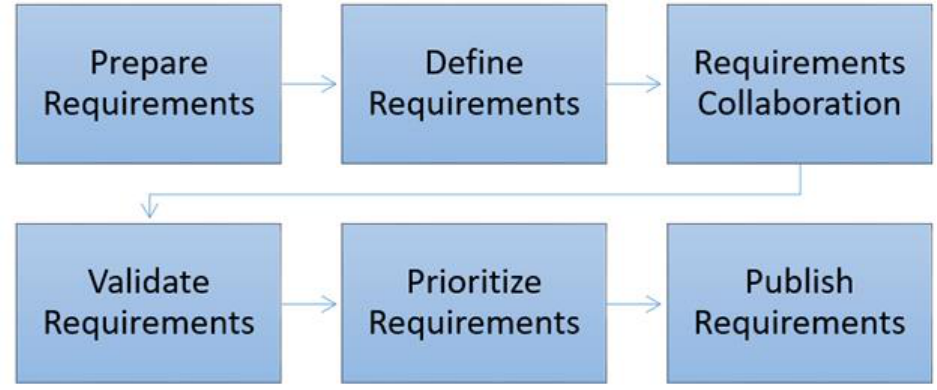

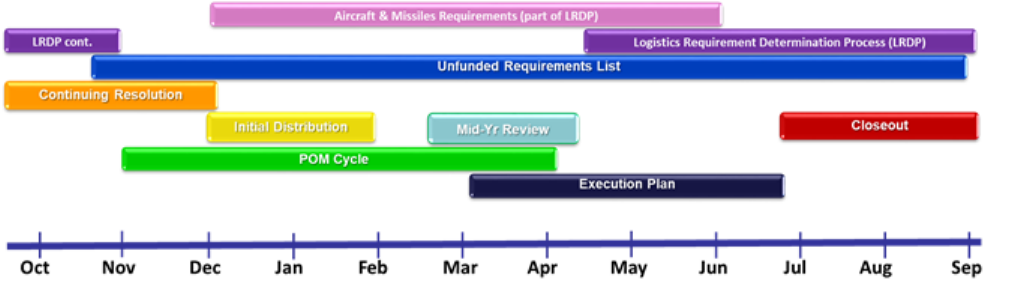

Figure 4.1. LRDP Flow. ............................................................................................................. 44

4.2. LRDP Phases. .......................................................................................................... 44

4.3. General Requirements Management. ....................................................................... 45

4.4. Explanation of Risk Categories. .............................................................................. 47

Chapter 5—PROGRAM OBJECTIVE MEMORANDUM (POM) PROCESS 60

5.1. Overview. ................................................................................................................. 60

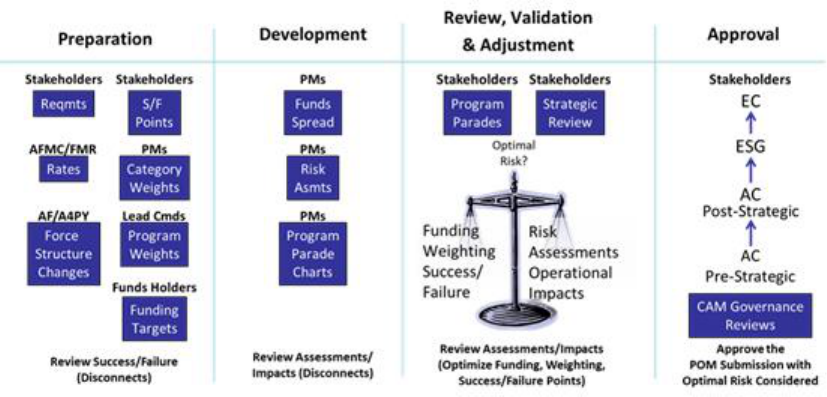

Figure 5.1. POM Phases. ............................................................................................................ 60

5.2. Phase One - Preparation Phase. ............................................................................... 60

5.3. Phase Two - Development Phase. ............................................................................ 61

5.4. Phase Three - Review, Validation, and Adjustment Phase. ..................................... 62

5.5. Phase Four - Approval Phase. .................................................................................. 62

Chapter 6—EXECUTION PLAN (EXPLAN) PROCESS 64

6.1. Overview. ................................................................................................................. 64

Figure 6.1. ExPlan Process. ........................................................................................................ 64

6.2. Phase One - Preparation Phase. ............................................................................... 64

6.3. Phase Two - Development Phase. ............................................................................ 65

6.4. Phase Three - Review, Validation & Adjustment Phase. ........................................ 66

AFMAN63-143 18 DECEMBER 2020 5

6.5. Phase Four - Approval Phase. .................................................................................. 66

6.6. Post-Approval Activities. ......................................................................................... 67

Chapter 7—EXECUTION PROCESS 68

7.1. Overview. ................................................................................................................. 68

Figure 7.1. Execution Activities Timeline. ................................................................................ 68

7.2. Weapon System Sustainment Requirements............................................................ 68

7.3. Funding. ................................................................................................................... 69

7.4. Forecast and Actual Obligation Updates. ................................................................ 69

7.5. Out Of Cycle (OOC) Process. .................................................................................. 70

7.6. Unfunded Requirement Requests. ........................................................................... 71

Chapter 8—COST PER FLYING HOUR (CPFH) PROGRAM 72

8.1. Overview. ................................................................................................................. 72

Figure 8.1. CPFH Execution Process. ........................................................................................ 72

8.2. Authorized CAM CPFH Supplies. ........................................................................... 72

Table 8.1. Authorized CPFH Supplies. ..................................................................................... 73

8.3. Baseline Validation for Authorized CPFH Supplies................................................ 73

8.4. Requirements Process for CPFH Supplies. .............................................................. 73

8.5. Finalize CPFH Supply Requirements. ..................................................................... 74

8.6. Building and Managing AvPOL Requirements. ...................................................... 74

8.7. Depot Working Capital Fund (DWCF) Bill. ............................................................ 75

8.8. Disbursements and Reimbursements. ...................................................................... 75

Attachment 1—GLOSSARY OF REFERENCES AND SUPPORTING INFORMATION 76

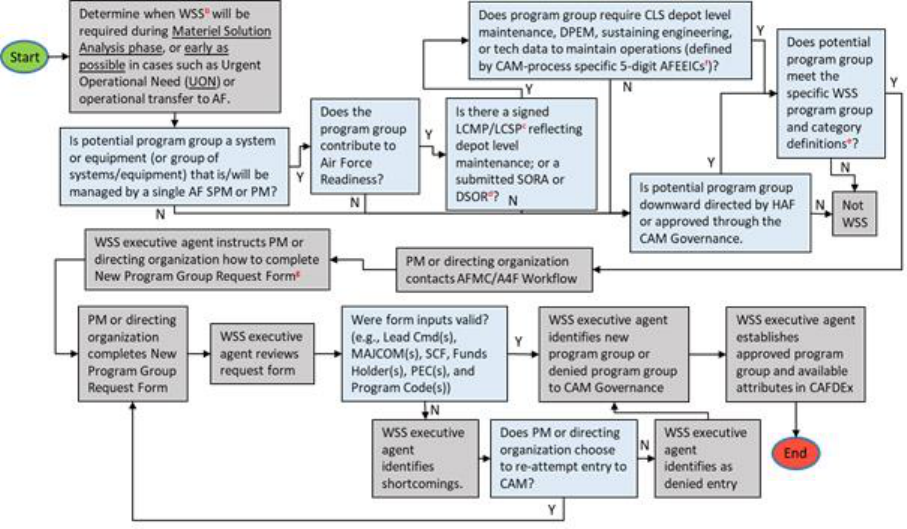

Attachment 2—PROGRAM GROUP ENTRY TO WSS DECISION TREE 90

Attachment 3—FAILURE POINT DEFINITIONS BY RISK CATEGORY 93

Attachment 4—OUT OF CYCLE THRESHOLD AND APPROVAL CRITERIA 95

6 AFMAN63-143 18 DECEMBER 2020

Chapter 1

INTRODUCTION

1.1. Overview. Centralized Asset Management (CAM) is the management and execution of

sustainment funding by one AF process owner. AFMC is the designated AF Executive Agent in

accordance with AFI 63-101/20-101. CAM-associated funding includes depot-level weapon

system sustainment (WSS) and active-duty AF Cost per Flying Hour (CPFH) program.

1.2. Applicability. This AFMAN applies to all program managers (PMs) and Major Commands

(MAJCOMs) utilizing CAM-associated funding or involved in sustainment requirements

determination. AF Special Operations Command (AFSOC), ANG, AFRC, and USSF utilize

CAM processes and schedules, but manage their own requirements validation and funds

execution processes.

1.3. Scope.

1.3.1. CAM processes provide enterprise management at the AF level by focusing resources

on AF priorities. CAM funding encompasses the AF WSS enterprise and the CPFH program.

Within WSS, there are four business process areas managed as part of CAM: depot

purchased equipment maintenance (DPEM), contractor logistics support (CLS), sustaining

engineering (SE), and technical orders (TOs).

1.3.2. The DPEM business process includes multiple sub-categories: aircraft and missile

requirements (AMR), engine maintenance, area support/base support/local manufacturing

(A/B/M), software maintenance, storage, exchangeables, and other major end items (OMEI).

Additionally, the first DPEM sub-category, AMR, has three supporting processes:

Engineering Requirements Review Process (ERRP), the Bill of Work (BOW) process, and

Maintenance Requirements Supportability Process (MRSP).

1.3.3. The CPFH program covers costs that directly support the following: the launch,

recovery, inspection, servicing, and maintenance of an aircraft; the inspection, servicing, and

maintenance of an aircraft component or a piece of support equipment that directly supports

aircraft maintenance; or the fuel used in the operation of aircraft or support equipment that

directly supports aircraft maintenance and fuel. The CPFH budget is comprised of the

following components: depot-level reparables (DLR), spares, and exchangeables,

consumable supplies, and aviation petroleum, oil, and lubricants (AvPOL).

1.4. CAM Governance.

1.4.1. AFMC/A4F and AFMC/FMM provide oversight over the CAM process through the

approved governance structure. The Advisory Council (AC), Executive Steering Group

(ESG), and Executive Committee (EC) comprise the CAM governance structure. A list of

current advisors, members, and co-chairs are located on the CAM SharePoint® at

https://usaf.dps.mil/:f:/r/teams/11015/CAM%20Document%20Library/CAMTEL%20(

CAM%20Training%20Hub)/00.%20Getting%20Started/01.%20Branch%20Org%20C

harts%20%26%20Governance%20Structure?csf=1&web=1&e=16zT4j.

1.4.2. The CAM governance structure ensures continuous process improvements are

documented and implemented as required. The governance structure also manages CAM

AFMAN63-143 18 DECEMBER 2020 7

technical content, releases process data calls to all stakeholders, and participates in process

collaboration and reviews. Voting membership is established at each level with chairs having

final responsibility.

1.4.3. The frequency of CAM governance structure meetings are driven by major planning,

programming, budgeting and execution (PPB&E) milestones, usually to develop risk-

assessed positions in support of the Program Objective Memorandum (POM) and Execution

Plan (ExPlan).

1.4.4. The AC serves as the advisory board to HQ AFMC CAM Executive Agent. Process

development and execution should be worked at the lowest level through integrated process

teams.

1.4.4.1. Chair. Co-chaired by the CAM chiefs (i.e., Product Support Division

(AFMC/A4F) and CAM Financial Management Division (AFMC/FMM)).

1.4.4.2. Voting Members. Each of the following organizations get one vote during the

AC: AFMC; Air Combat Command (ACC); AMC; AFRC; ANG; USSF; AFSOC; Air

Force Global Strike Command (AFGSC); Air Force Flight Standards Agency; Air

Education and Training Center (AETC); Operations, Plans and Requirements (AF/A3);

Logistics, Engineering and Force Protection (AF/A4); Logistics and Product Support

(SAF/AQD); and, Assistant Secretary of the Air Force, Financial Management and

Comptroller (SAF/FM).

1.4.5. The ESG is the decision making body for the process development effort and is

responsible for resolving issues that cannot be resolved at lower levels.

1.4.5.1. Chair. Senior Executive Director (AFMC/CA).

1.4.5.2. Voting Members. Each of the following organizations get one vote during the

ESG: AFMC, ACC, AMC, AFRC, ANG, USSF, AFSOC, AFGSC, Air Force Flight

Standards Agency, AETC, SAF/AQD, AF/A4, SAF/FM, and AF/A3.

1.4.6. The EC is the decision making body that provides oversight for the CAM process, sets

goals, and provides vision and resources. The CAM EC meets quarterly or as needed.

1.4.6.1. Tri-Chair. Deputy Commander, Air Force Materiel Command (AFMC/CD),

Deputy Assistant Secretary for Budget (SAF/FMB), and AF/A4.

1.4.6.2. Voting Members. Each of the following organizations get one vote during the

EC: AFMC, ACC, AMC, AFRC, ANG, USSF, AFSOC, AFGSC, AETC, SAF/AQD, and

AF/A3.

1.5. CAM Process and Process Flow. The CAM process, as identified in Figure 1.1 below,

entails requirements definition and refinement, planning and programming, and budget and

execution to provide AF-wide visibility for WSS requirements. CPFH requirements utilize the

Spares Requirements Review Board (SRRB) process in accordance with AFMAN 23-120,

Spares Requirement Review Board (SRRB).

8 AFMAN63-143 18 DECEMBER 2020

Figure 1.1. The CAM Process.

1.5.1. Lead MAJCOMs coordinate with air staff and supported commands (e.g., United

States Air Forces in Europe, Pacific Air Force, AFRC, etc.) to provide the PM and program

offices with their weapon systems desired level of performance. Requirements from the lead

MAJCOM(s) utilize the CAM information technology (IT) system of record to provide

requirements to AFMC.

1.5.2. The PMs and program offices use guidance, direction, and where applicable, flying

hours (FHs), to develop valid and defendable requirements. Stakeholders collaborate on

requirements during the Logistics Requirements Determination Process (LRDP) and publish

requirements on or around November 1 of each year. The published requirements are

provided to CAM and the applicable Funds Holder for use in the development of the POM

and ExPlan.

1.5.3. The Funds Holder works with the program offices and lead MAJCOMs to achieve a

CAM governance-approved POM and ExPlan each year to be submitted to Air Staff. Air

Staff works to receive an approved budget that meets the Strategic Defense Objectives and

distributes dollars in each year of execution to the appropriate Funds Holder (e.g., Operating

Agency Code (OAC) 41-ANG, OAC 62-AFRC, OAC 65-TWCF/AMC, and OAC 87-CAM).

1.5.4. The Funds Holder distributes dollars to the program offices for execution.

1.5.5. Program offices send their dollars via funding documents to the desired source of

repair (SOR) and source of supply which execute the dollars received.

1.5.6. Organic depot repair facilities and the CPFH program reimburse the AF Working

Capital Fund (AFWCF). Program offices pay for organic depot repair based on a BOW with

hours multiplied by a depot rate which the Air Force Sustainment Center Working Capital

Fund (WCF) establishes two years in advance.

1.5.7. Service providing contractors (e.g., contract DPEM, interservice repair, CLS

contractors, contract SE, and TOs) generally execute dollars directly and return excess

funding to the PM to flow up to the Funds Holder.

1.5.8. Headquarters Air Force (HAF) staff has visibility in all steps and processes which

ensure standard, repeatable, and auditable PPB&E processes within the CPFH and WSS

enterprise execution.

AFMAN63-143 18 DECEMBER 2020 9

1.6. Program Group Entry to Total Force WSS.

1.6.1. To be considered for entry into the CAM WSS portfolio, the responsible PM shall

ensure the new program group, program (including Section 804 programs), or system meets

the entry criteria as identified in the Program Group Entry to WSS Decision Tree (see

Attachment 2). (T-1).

1.6.2. If the requesting program office determines the entry criteria within Attachment 2

have been met, a “New Program Group, Program, or System Request” form should be

completed and submitted by the requesting program office to the AFMC/A4FR Workflow.

1.6.3. The CAM Service Core Team Lead will coordinate the remaining signatures on the

New Program Group, Program, or System Request form. (T-3). The full routing of the form

is approved by an AFMC/A4F CAM Branch Chief before any new program group, program,

or system is allowed to enter CAM.

1.6.4. The WSS Decision Tree and the “New Program Group, Program, or System Request”

form are located on the CAM SharePoint® at

https://usaf.dps.mil/:f:/r/teams/11015/CAM%20Document%20Library/CAMTEL%20(

CAM%20Training%20Hub)/00.%20Getting%20Started/00.%20New%20Program%2

0Group,%20Program,%20or%20System%20Request?csf=1&web=1&e=wsBkAi.

1.7. Flying Hour Program (FHP). Per Department of the AF Policy Directive (DAFPD) 11-1,

Flying Hour Program, AF/A3, with coordination from the National Guard Bureau for ANG and

AFRC, provides guidance for resource advocacy and oversight of the Total Force FHP.

1.7.1. The FHP is a closely monitored program that produces the FHs necessary to develop

and sustain combat airpower. Separate from the normal acquisition processes, interested PMs

shall direct requests to become a part of the total force FHP to the Deputy Chief of Staff,

Operations, AF/A3. (T-1).

1.7.2. Per AFI 65-503, US Air Force Cost and Planning Factors, the CPFH is a subset of

logistics factors that are used to forecast the AF FHP budget requirement. Therefore, CPFH

factors will be developed as required to support the total force FHP.

10 AFMAN63-143 18 DECEMBER 2020

Chapter 2

ROLES AND RESPONSIBILITIES

2.1. Headquarters AF Directorates.

2.1.1. Provide strategic guidance and advocacy through the Logistics Panel and other

corporate structure forums.

2.1.2. Support the CAM governance structure.

2.2. AF/A3.

2.2.1. In addition to the responsibilities listed in paragraph 2.1, delivers monthly flying

hour (FH) reports required in support of the WCF bills.

2.2.2. Works with SAF/FMB and CAM on execution year emerging issues.

2.2.3. Provides FH for the Future Years Defense Program (FYDP), to include a planning

factor and final position.

2.2.4. Provides an annual execution guidance memo for the Total Force FHP.

2.3. AF/A4.

2.3.1. In addition to the responsibilities listed in paragraph 2.1, provides the Force

Structure Decision Memorandum file for aircraft inventory as outlined in AFI 16-402,

Aerospace Vehicle Programming Assignment, Distribution, Accounting, and Termination.

2.3.2. Provides the budget position to the applicable Funds Holder and provides POM

technical and strategic guidance.

2.3.3. Provides advocacy through Logistics Panel and other corporate structure forums.

2.3.4. Coordinates Force Structure changes with AF/A8, SAF/FMB, Deputy Assistant

Secretary for Cost and Economics (SAF/FMC), AF/A3, and key SRRB stakeholders for the

FHP.

2.3.5. Advocates for additional funds in support of emerging AF priorities and informs CAM

of impending force structure changes during the execution process.

2.3.6. Serves as the voice for WSS to AF corporate structure.

2.3.7. Provides the deferral report to the Office of the Secretary of Defense (OSD).

2.4. Budget Operations Directorate (SAF/FMBO).

2.4.1. Provides initial funding budget outlay governing execution year to the applicable

Funds Holder for the development of the Execution Plan (ExPlan).

2.4.2. Receives the final ExPlan position after approval from the CAM governance.

2.4.3. Provides execution year funding and financial guidance

2.4.4. Informs CAM on funding changes directed down by AF corporate structure.

2.4.5. Publishes Air Force (AF) Element of Expense/Investment Codes (EEIC) (AFEEICs)

and Program Element Codes (PEC) within the Financial Management Data Quality Service.

AFMAN63-143 18 DECEMBER 2020 11

2.4.6. Oversees the FHP execution of dollars and funding.

2.5. Air Force Material Command Commander (AFMC/CC).

2.5.1. Authorizes CAM guidance and training as coordinated through the CAM EC.

2.5.2. Authorizes the CAM governance structure as the approving body for CAM procedures

and POM deliverables.

2.6. Working Capital Funds Division (HQ AFMC/FMR).

2.6.1. Responsible for the AF Working Capital Fund (WCF).

2.6.2. Provides the organic DPEM rates to AFMC/A4F during the POM process.

2.6.3. Provides updates to the organic DPEM rates previously provided.

2.7. AF CAM Executive Agent.

2.7.1. Comprises of AFMC/A4F and AFMC/FMM. The have combined and individual

responsibilities. AFMC/A4F and AFMC/FMM both:

2.7.1.1. Provide enterprise-level oversight for the AF WSS processes and the spread of

funds against approved requirements. Serve as the integrator, facilitator, and continuous

process improvement champion.

2.7.1.2. Manage the AF WSS portfolio through approved, standard, and repeatable

processes.

2.7.1.3. Manage the AF WSS account through oversight and validation of requirements

and performs activities as the Executive Agent.

2.7.1.4. Ensure out of cycle (OOC) actions are reviewed, processed, and approved in the

CAM information technology (IT) system of record.

2.7.1.5. Manage and oversee the planning, programming, budgeting, & execution

(PPB&E) of active-duty AF WSS.

2.7.1.6. Engage with key stakeholders to ensure the AF’s most important sustainment

needs are met with the funding available.

2.7.1.7. Ensure available funding is provided to the highest priorities based on the OSD

and Secretary of the AF guidance such as projected need dates, program or mission risk,

contract period of performance, aircraft availability, prior year execution, response to

natural disasters, impacts to readiness, and urgent requirements to prevent loss of life

and/or aircraft.

2.7.1.8. Validate final funding levels through CAM governance.

2.7.1.9. Coordinate on all policy agreements or procedures that impact CAM funding

and commitments.

2.7.1.10. Comply with higher headquarters taskings, call letters, and policy letters.

2.7.2. AFMC/FMM.

2.7.2.1. Provides ExPlan kickoff and training to programs and lead commands.

12 AFMAN63-143 18 DECEMBER 2020

2.7.2.2. Sets funding baseline for initial distribution in the execution year and facilitates

and oversees program office funds spread throughout the execution year.

2.7.2.3. Ensures program offices reconcile their obligations on a monthly basis within

the CAM IT system of record.

2.7.2.4. Interfaces with applicable agencies for AvPOL to reimburse or disburse for

missions flown on behalf of active-duty AF organizations and as approved by AF/A3 and

SAF/FMBOO.

2.7.2.5. Manages Contingent Liabilities.

2.7.2.6. Resolves shortfalls in the execution year utilizing the unfunded process.

2.7.2.7. Oversees funds distribution and balancing within the program groups.

2.7.2.8. Monitors funds control and execution of AvPOL funds and disbursements.

2.7.2.9. Validates and processes active-duty AF Depot Working Capital Fund (DWCF)

bill for authorized CPFH supplies.

2.7.2.10. Provides AvPOL funds disbursements to agencies that fly in support of

approved active-duty AF missions and are CPFH model driven.

2.7.3. AFMC/A4F.

2.7.3.1. Manages the CAM LRDP timeline, checklist, and kickoff training. Also

approves and validates data calls and integrates all stakeholder requirements.

2.7.3.2. Responsible for development and management of CAM training program.

2.7.3.3. Collaborates on requirements and ensures all requirements with non-concur

status are resolved or mediated.

2.7.3.4. Provides direct assistance, oversight, and analysis to all stakeholders in

developing and documenting WSS requirements and POM inputs.

2.7.3.5. Responsible for developing the CAM POM by providing POM kickoff training

to stakeholders, consolidating and integrating inputs, defending requirements, and

approving and validating data calls.

2.7.3.6. Validates final funding levels and risk through CAM governance.

2.7.3.7. Manages a listing of all CAM funded CPFH supply accounts.

2.7.3.8. Develops the Budget Code (BC) 8 requirements for active-duty AF via the

SRRB process.

2.7.3.9. Responsible for the CAM IT system of record as the PM and functional

manager.

2.7.3.10. Performs requirements analysis and reports metrics to stakeholders.

2.7.3.11. Validates requirement reconciliation and prepares deferral report.

2.7.3.12. Ensures program offices reconcile their obligations within the CAM IT system

of record on a quarterly basis.

AFMAN63-143 18 DECEMBER 2020 13

2.7.3.13. Manages CAM policy and provides guidance through this publication,

AFMAN 63-143.

2.8. MAJCOM/CCs.

2.8.1. Provide operational perspectives and recommendations that affect their respective

weapon system requirements.

2.8.2. Provide MAJCOM WSS point of contacts (POCs) who review, validate, prioritize and

coordinate requirement inputs, as applicable.

2.9. Lead/Supported MAJCOMs.

2.9.1. Support CPFH requirements development and variance analysis.

2.9.2. Assist CAM/Funds Holder(s) with validation and maintenance of base-level supply

accounts to ensure and validate accounts are accurately coded.

2.9.3. Correct and reverse erroneous or unauthorized purchases against CAM CPFH supply

accounts.

2.9.4. Approve consumable Consolidated Sustainment Activity Group-Retail (CSAG-R), BC

9 requirement rates as submitted by SAF.

2.9.5. Provide service core function operational risk assessments and associated impact

statements, as well as other information needed to assess service core function as part of the

overall portfolio.

2.10. Lead Command POC.

2.10.1. During the LRDP, establishes desired capability levels, collaborates on requirements,

ensures all non-concurs have been resolved or mediated, and works with program offices to

prioritize requirements.

2.10.2. During the POM process, sets desired risk levels and weighting of programs within

their respective service core function(s), assists programs with operational impacts on

program parade slides, and provides funding trade-off options within ‘owned’ weapon

systems and service core functions to minimize risk to highest prioritized weapon system(s).

2.10.3. During ExPlan development, provides funding trade-off options within owned

weapon systems to minimize risk to highest prioritized weapon system(s) and provides

weights for each program within each service core function.

2.10.4. During the execution year, advocates for program requirements based on mission

need, coordinates on OOCs, and provides the prioritized 1 to N list of WSS unfunded

requirements.

2.11. Supported Commands.

2.11.1. Provide operational perspectives and recommendations that affect the requirements

process (e.g., weapon system availability, capability, pilot throughput, etc.) to the lead

command.

2.11.2. Collaborate on applicable requirements as desired.

2.11.3. Ensure all non-concurs are resolved or mediated.

14 AFMAN63-143 18 DECEMBER 2020

2.12. Program Executive Officers (PEOs).

2.12.1. Ensure assigned PMs define, review, validate, and publish accurate, reliable, timely,

and executable requirements.

2.12.2. Ensure requirements are properly documented within the CAM IT system of record

for their programs.

2.13. Funds Holder POCs.

2.13.1. Includes active-duty AF (as managed by CAM), ANG, AFRC, TWCF, USSF, and

AFSOC (only for CPFH).

2.13.2. Coordinate with the lead command POCs in validating, prioritizing and budgeting all

requirements.

2.13.3. Collaborate on requirements and ensure all non-concurs have been resolved or

mediated.

2.13.4. Work with program offices to prioritize requirements.

2.13.5. Establish funding levels for applicable appropriation for each program group.

2.13.6. Perform initial funds spread in the CAM IT system of record.

2.13.7. Spread approved funding received from SAF/FMBO across its weapon systems’

requirements using the CAM risk model during the ExPlan.

2.13.8. Coordinate on OOCs.

2.13.9. Manage funds according to existing approved requirements based on AF priorities,

and the mitigation solution for WSS unfunded requirements within their OAC.

2.14. Program Manager (PM).

2.14.1. Develops detailed requirements to meet desired capabilities and spreads funding to

minimize risk and maximize capability to the warfighter.

2.14.2. Develops and updates detailed requirements to sustain desired level of capability.

2.14.3. Ensures documentation of PM or PM designee response to requirements with non-

concur status within the CAM IT system of record. The PM shall adjudicate all requirements

with non-concur status prior to publishing requirements for the POM. (T-1).

2.14.4. Validates, prioritizes, and publishes requirements according to established timelines.

2.14.5. During the POM process, the PM is responsible for the following tasks:

2.14.5.1. Establishes risk category weights;

2.14.5.2. Provides information to and gathers information from lead MAJCOMs to

support operational risk assessments;

2.14.5.3. Prioritizes requirements from 1 to N in collaboration with MAJCOM users;

2.14.5.4. Spreads allocated funding to minimize risk and maximize capability to the

warfighter in the CAM IT system of record;

2.14.5.5. Provides impact statements at various funding scenarios; and,

AFMAN63-143 18 DECEMBER 2020 15

2.14.5.6. Develops program parade slides.

2.14.6. During the ExPlan process, the PM is responsible for the following tasks:

2.14.6.1. Establishes risk category weights;

2.14.6.2. Prioritizes requirements from 1 to N in collaboration with MAJCOM users;

and,

2.14.6.3. Spreads allocated funding to minimize risk and maximize capability to the

warfighter in the CAM IT system of record.

2.14.7. During the execution year, manages program requirements, funding, projected

obligations, actual obligations and contingent liabilities, processes OOCs, and identifies

unfunded requirements in the CAM IT system of record.

2.14.8. During the AMR process, the PM is responsible for the following tasks:

2.14.8.1. Manages and coordinates the Engineering Requirements Review Process

(ERRP) and the Maintenance Requirements Supportability Process (MRSP);

2.14.8.2. Hosts the annual review to include facilitating collaboration meetings;

2.14.8.3. Negotiates and resolves complex maintenance concerns to ensure scheduled

maintenance tasks, hours, and narratives are updated annually;

2.14.8.4. Completes a depot customer workload agreement (DCWA) for the year of

execution for organic depot maintenance workload;

2.14.8.5. Appoints an Engineering Requirements Review (ERR) Manager;

2.14.8.6. Determines which current or existing tasks to include in the annual

Development Packet (DEV PAC) reviews; and,

2.14.8.7. Ensures that the appropriate trigger code is used to forecast materiel when there

is a significant change in future requirements for a Defense Logistics Agency (DLA)-

managed consumable item.

2.14.9. Responsible for monthly obligation reconciliation within the CAM IT system of

record which is an input to the deferral report.

2.14.10. Appoints PM designee via email to HQ AFMC A4FR Workflow.

2.15. Chief Engineer.

2.15.1. Serves as the final authority for the technical requirements in AMR.

2.15.2. Chairs the Requirements Review Board during the ERRP.

2.15.3. Serves as the final authority for AMR software maintenance (e.g., AFEEICs 54001,

54002, and 56000) and SE requirements (e.g., AFEEICs 57834, 57836, 58300, and 583OR).

2.16. Engineering Requirements Review (ERR) Manager.

2.16.1. The PM appoints the ERR manager and the ERR manager oversees, manages, and

facilitates the ERRP.

16 AFMAN63-143 18 DECEMBER 2020

2.16.2. Coordinates with the program office, Production Management and Maintenance

Managers to ensure a thorough review and validation effort takes place for all new, amended

or deleted DEV PACs.

2.16.3. Updates the ERRP Performance Matrix quarterly.

2.16.4. The ERR Manager receives and documents the proposed requirement within the

DEVPAC.

2.16.5. Plans, schedules, and tracks all new, amended, or deleted DEV PACs through

completion; provides AFMC/CAM with a list of completed DEV PACs annually after the

ERRP is complete.

2.16.6. Coordinates the Requirements Review Board (when requested by the chair, the Chief

Engineer) for the defined requirement.

2.16.7. Documents the final actions and outcomes from the Requirements Review Board

(e.g., approve, disapprove, rework, approve on subsequent submission).

2.16.8. Performs follow up(s) on any issues the BOW or requirements supportability teams

may have with the scheduled maintenance task.

2.16.9. Serves as the gatekeeper to maintain, coordinate, and facilitate corrective actions for

DEV PAC revisions, updates, and changes.

2.16.10. Plans, schedules, and tracks a review of completed DEV PACs. Ensures 100%

review of the completed DEV PACs over the course of the programmed depot maintenance

(PDM) interval.

2.16.11. Coordinates with the program office, Production Management, and Maintenance

Managers to select and prioritize tasks for review.

2.17. Program Office Engineer.

2.17.1. Populates the proposed requirements data fields and elements in the DEV PAC.

2.17.2. Leads collaborative meeting discussion on statement of work, technical order, and

Time Compliance Technical Order (TCTO) procedures.

2.17.3. Briefs what is included in the DEV PAC data fields and list of materiel (LOM).

2.18. Program Office Equipment Specialist (ES).

2.18.1. Works in conjunction with the program office engineer to populate the requirements

data fields and elements on the DEV PAC, Part I, blocks one through 25.

2.18.2. Assists the engineer with the collaborative meeting discussion on statement of work,

technical order, and TCTO procedures. Briefs what is included in the LOM.

2.19. Program Office Logistics Specialist.

2.19.1. Evaluates the new or updated task materiel list to perform an initial assessment of

availability and identify long-lead items in the ERRP.

2.19.2. Ensures proper notification when there is a significant change in future requirements

for a DLA-managed consumable item.

AFMAN63-143 18 DECEMBER 2020 17

2.20. Maintenance Groups. Perform trend analysis on tasks with occurrence factors less than

100% and tasks with unpredictable workload during the AMR process.

2.21. Work Specification Manager. During the AMR process, certifies and publishes the work

specification.

2.22. Air Force Sustainment Center (AFSC) 448th Supply Chain Management Wing

(SCMW). During the AMR process, provides supportability assessment on parts managed by

the 448 SCMW.

2.23. Defense Logistics Agency (DLA). Provides an initial assessment on asset availability to

assist the program office in determining the year of planned task execution in accordance with

AFMC Instruction (AFMCI) 23-105, Planning for DLA Managed Consumables (PDMC).

2.24. Depot Maintenance Planner. Validates Direct Product Standard Hours (DPSH) on

existing scheduled depot maintenance tasks selected for annual review. This validation occurs

concurrently with the ERRP development and review of the DEV PACs for existing tasks.

18 AFMAN63-143 18 DECEMBER 2020

Chapter 3

AIRCRAFT AND MISSILE REQUIREMENTS (AMR) PROCESS

3.1. Overview.

3.1.1. The AMR process applies to all AF organizations that require and provide depot

maintenance on aircraft or missile systems utilizing CAM funding and includes all work

performed organically or via interservice agreement. This process also applies to contract

depot maintenance workload.

3.1.2. The AMR process covers AFEEICs 54101, 54102, 56010, 54201, 54202, 56020, and

repair group category (RGC) A, B, C, and D. This chapter outlines how to develop, review,

validate, and approve depot-level maintenance and repair for aircraft and missile systems at

the task level.

3.2. Supporting Guidance.

3.2.1. AFMCI 21-102, Analytical Condition Inspection (ACI) Programs, provides guidance

and procedures for establishing and monitoring ACI programs for aerospace equipment. ACI

programs are established to reveal defects that may not otherwise be detected through normal

technical order and PDM inspections. Data generated from ACIs is used to refine or create

mandatory aircraft inspection programs (e.g., field and depot programs).

3.2.2. AFMCI 21-103, Reliability-Centered Maintenance (RCM) Programs, provides

guidance and procedures for establishing and monitoring preventive maintenance programs

for aerospace equipment using RCM methodology. RCM analysis is used to develop

scheduled inspection and maintenance requirements and reveals requirements for potential

PDM and ACI tasks.

3.2.3. AFMCI 21-104, Controlled Interval Extension (CIE) Programs, provides guidance

and procedures for establishing and monitoring CIE programs for aerospace equipment. CIE

programs are established to control conditions for extending maintenance and inspection

intervals without sacrificing safety of flight or reliability.

3.2.4. PDM intervals are determined by evaluating aircraft or missile safety, reliability, and

mission requirements. TO 00-25-4, Depot Maintenance of Aerospace Vehicles and Training

Equipment, outlines the technique used to determine the appropriate CIE sample size based

on the force size of the mission design series (MDS) being evaluated under the CIE

programs.

3.2.5. The Aircraft Structural Integrity Program (ASIP) establishes a timed-phased set of

required actions to be performed to ensure the structural integrity of the aircraft. Reference

AF Policy Directive (AFPD) AFPD 63-1/20-1, Integrated Life Cycle Management, DAFI 63-

140, Aircraft Structural Integrity Program and Air and Space Equipment Structural

Management, and MIL-STD-1530D, DoD Standard Practice, for additional ASIP guidance.

3.2.6. AFMCI 21-100, Depot Maintenance Management documents additional information

on RGCs.

AFMAN63-143 18 DECEMBER 2020 19

3.3. Aircraft Requirements.

3.3.1. Funds holder funds are used to support all depot-level maintenance requirements for

aircraft in RGC A and B.

3.3.1.1. RGC A designates programmed requirements. Programmed requirements are

those which are scheduled on a calendar or time cycle basis.

3.3.1.2. RGC B designates field teams and unprogrammed maintenance. Unprogrammed

maintenance requirements generate unpredictably. If a field team is used, RGC B organic

rates and contract prices include labor costs only. The owning unit will order required

material against its local flying hour account. (T-3).

3.3.2. Aircraft maintenance, such as defueling, disarming, and flight prep, is generally paid

for by the Funds Holder who funds the driving workload. Driving workload is the primary

reason an aircraft is scheduled into a repair facility.

3.3.3. PDM and ACI aircraft requirements use DPEM customer funding under RGC A.

These requirements must be presented to and approved by the PM with coordination from the

MAJCOM. (T-3).

3.3.4. Airframe condition evaluation and on-condition maintenance for rotary winged

aircraft are funded under DPEM RGC A.

3.3.5. The pre-induction inspection is accomplished months before the aircraft enters its

scheduled depot maintenance. This provides sufficient lead time for improving the real-time

maintenance requirements that establishes the known aircraft condition baseline. This leads

to a well-defined maintenance support plan for the submitted depot-level work package.

Detailed pre-induction inspection instructions are documented in TO 00-25-4.

3.3.6. Maintenance assist requests submitted according to AF Technical Order (AFTO) 00-

25-107, Maintenance Assistance, from the customer for depot assistance are funded under

RGC B. The Air Logistics Complex (ALC) may fulfill the requirement using a field team or

by repairing the aircraft at a depot-level facility.

3.3.7. Negotiated organizational and intermediate level aircraft maintenance performed by

depot-level personnel at the request of the user is a DPEM requirement. This type of work

must be negotiated between the customer, Funds Holder(s), lead command, PM, and the

SOR. (T-3). Organizational and intermediate level maintenance can also be accomplished via

an AFTO Form 103, Aircraft/Missile Condition Data, request certified by the MAJCOM as

mission essential and beyond its current capability.

3.3.8. The aircraft depot-level modification installation is funded with appropriation 3010,

Budget Program 1100.

3.3.9. Damage that is not due to reasonable wear and tear and exceeds $250,000 total repair

cost is called aircraft damage repair. Operations and Maintenance (O&M) funding pays to

recover the aircraft to a flying condition. SE EEIC 583 pays for engineering evaluations to

determine the cause of the damage. EEIC 583 is generally used for contract support only.

However, it is possible to use organic resources for this purpose, but the funds must first be

realigned to AF EEIC 583OR. The DPEM requirement consists of the cost of examining the

damaged aircraft by contract or organic depot-level maintenance personnel to determine the

20 AFMAN63-143 18 DECEMBER 2020

cost of repair and to assemble a materials list. The labor and material used to repair the

aircraft is also a valid DPEM requirement.

3.4. Missile Requirements.

3.4.1. Requirements in RGC C and D support all depot-level maintenance activities required

for AF missile systems. RGC C designates programmed requirements, i.e., those that are

scheduled on a cyclical basis. RGC D is used for unprogrammed maintenance and field

teams. If a field team is used, RGC D organic rates and contract prices include labor costs

only.

3.4.2. The owning unit orders required material against its local funds for:

3.4.2.1. Induction and withdrawal of operational missiles from storage and the

maintenance to preserve them while in storage. Storage and maintenance is the

permanent, on-site environmentally-controlled storage and preservation maintenance

performed by a SOR other than the Aerospace Maintenance and Regeneration Group

(AMARG).

3.4.2.2. PDM and ACI for defects, deterioration, or corrosion in the air-vehicle

equipment and operational ground equipment.

3.4.2.3. Disassembly for shipment. Assembly or reassembly to an operational condition.

3.4.2.4. Preparation for shipment.

3.4.2.5. Depot field teams (DFTs) located at each operational wing that accomplishes

required phase tasks to include:

3.4.2.5.1. Testing and subsequent repair of a missile for structural integrity.

3.4.2.5.2. Analysis such as fatigue analysis of a component or section of a missile to

determine if the class of assets is beyond economical repair.

3.4.2.5.3. Reclamation and repair of stock-fund exempt missile components.

3.4.2.5.4. Depot-level repairs for damage that was not caused by fair wear and tear.

3.4.2.5.5. Inspection TCTO.

3.4.2.5.6. Maintenance assistance requests (in accordance with AFTO 00-25-107)

accomplished by organic or contract field teams (CFTs).

3.4.2.5.7. Aging and surveillance tasks.

3.4.2.5.8. Demilitarization and disposal.

3.4.2.5.9. Fault isolation and repair.

3.4.2.5.10. Computed tomography of intercontinental ballistic missile (ICBM) rocket

motors.

3.4.3. Unprogrammed, RGC D organic and contract maintenance requirements for the ICBM

weapon system are generated primarily by the use of program management, engineering

assessments, and the historical trend of past year obligations, as well as known program

changes, (e.g., PDM directions or the Strategic Arms Reduction Treaty). ICBM

unprogrammed requirements may result from:

AFMAN63-143 18 DECEMBER 2020 21

3.4.3.1. A deficiency identified by one of the PMs within the ICBM program group (e.g.,

guidance, propulsion, re-entry, or ground). Once a deficiency is identified, an integrated

product team should meet to develop a viable solution.

3.4.3.2. A risk to the program based on engineering assessments identified by the ICBM

Chief Engineer.

3.4.4. The Item Manager initiates an AFMC Form 800, Item Manager Workload Projection

Summary, and sends it to the Production Management Specialist (PMS). The PMS uses this

spreadsheet to determine if the requirement's SOR is either contract or organic and document

the quantity and time frequency of repair. The programmed, RGC C DPEM organic and

contract support requirements are computed by the parts forecasting system.

3.4.5. Emergency response teams for ICBM rocket motors and Propulsion System Rocket

Engines have been deemed not valid WSS or depot-level maintenance activities per AFMC

Financial Management Policy Division (AFMC/FMAP). AFGSC is responsible for

budgeting and funding for ICBM Emergency Response Teams outside the WSS process,

including hardiness surveillance electronic pulse program for ICBM Launch facilities, and

static-fire performance testing for ICBM rocket motors and propulsion-system rocket

engines.

3.5. Depot Schedule and Depot Customer Workload Agreement (DCWA).

3.5.1. Depot maintenance scheduling is required to facilitate an effective use of resources in

providing maximum weapon system availability to the warfighter. The purpose of the

DCWA is to define the scope of work, outline specific requirements, and specify customer

responsibilities for accomplishing organic pre- and post-depot-level maintenance for

inductions and deliveries of all specific weapon systems at ALCs.

3.5.2. The PM, in conjunction with MAJCOMs, ALC business office, maintenance, and

appropriate stakeholders, will develop and publish an official schedule annually by 1 July for

the next execution year plus draft two-years of the FYDP (at a minimum) aligned with the

approved AMR brochure. (T-3). The intent is to develop the official baseline schedule by tail

number, engineering requirement, quantity, or missile site.

3.5.3. The PM shall ensure the core elements of a depot schedule consists of the following:

tail number, missile, sites, quantity, induction date, target completion date, flow days, and

program or type of work (e.g., PDM, modification, etc.). (T-1).

3.5.4. In addition to the core elements, the optional following elements provide increased

value to the customer: program control number, owning unit or base, MDS, MAJCOM, SOR,

and additional requirements as needed (e.g., ACI).

3.5.5. Each PM is responsible for coordinating and completing a DCWA for the year of

execution for organic depot maintenance workload. At a minimum, the PM and the PM

equivalent from each of the following groups will coordinate on and sign the DCWA: lead

command; Funds Holder; MAJCOM logisticians; ALC maintenance group; and ALC

business office. (T-3).

3.5.6. All ANG aircraft and missile workload agreements are coordinated through National

Guard Bureau (NGB) Maintenance Division (NGB/A4M) and NGB Resources Division

(NGB/A4P) for signature.

22 AFMAN63-143 18 DECEMBER 2020

3.5.7. The PM will coordinate a memorandum requesting deviation from guidance if the

designated representatives in paragraphs 3.5.5 and 3.5.6 (if applicable) agree not to utilize a

DCWA. (T-3). The DCWA or the memo must be fully signed by all parties and in place not

later than 1 September for each year it is used. (T-1).

3.5.8. The PM, maintenance group, ALC Business Office, and MAJCOM(s) POC(s) (on

behalf of their respective units) will jointly agree on the DCWA. (T-1). The AMR work

specification is used as the basis for scheduled maintenance tasks to be accomplished,

whereas the AMR brochure is used as the basis for the scheduled maintenance sub-tasks and

hours associated with each weapon system in the agreement. Each PM and ALC local

operating instruction may provide guidance on format, title, and schedule for the DCWA.

The PM will provide copies of the workload agreement or the letter of deviation to

AFMC/A4FR workflow upon final approval and signature. (T-1). The PM will ensure the

DCWA is provided to all applicable stakeholders. (T-3).

3.5.9. At a minimum, the PM will ensure the DCWA addresses the following elements:

assessment period, flow days, induction configuration, key POCs, period of performance,

purpose, quality statement, required documents or references, duties, tasks, scope of work,

signature block(s) with dates, special instructions, and warranties. (T-1).

3.5.10. The PM, MAJCOM(s), POC(s), ALC maintenance group, and ALC Business Office

coordinates on deviations from the negotiated work package(s), support responsibilities, or

other agreements. The PM is responsible for ensuring the deviations have been approved and

those deviations are documented within the DCWA. (T-3).

3.6. Fixed Price Worksheet (FPWS).

3.6.1. The PM develops and coordinates the FPWS. The FPWS documents the agreement

between the weapon system PM and the ALC maintenance group for each tail or serial

numbered aircraft or missile system undergoing organic depot maintenance and other tasks

performed in conjunction with depot maintenance.

3.6.2. The FPWS applies to the following workloads: 3400-funded sustainment, 3600-

funded development, 3010- or 3020-funded modifications, foreign military sales or other

direct cite, and partnership workload.

3.6.2.1. MAJCOM specific requirements, are documented on the FPWS in the “other

negotiated maintenance” and “scheduled mods, TCTO, and other negotiated maintenance

(i.e., other than 3400 Funded)” sections.

3.6.2.2. The FPWS includes all tasks accomplished during depot maintenance that

generate revenue for the complex.

3.6.2.3. A template for the AFMC Standard FPWS is located on the CAM SharePoint®

at

https://usaf.dps.mil/:f:/r/teams/11015/CAM%20Document%20Library/CAMTEL%

20(CAM%20Training%20Hub)/01.%20Aircraft%20and%20Missile%20Requirem

ents%20(AMR)?csf=1&web=1&e=f0IGQa.

3.6.3. The FPWS is divided into the following four areas:

3.6.3.1. Area 1, the FPWS Header, identifies the tail or serial numbered aircraft or

missile system undergoing organic depot maintenance and other applicable data.

AFMAN63-143 18 DECEMBER 2020 23

3.6.3.2. Area 2, the Planned Depot Work (Fixed Price Area), documents the three

elements of the fixed price: basic, options, and over and above (O&A). This area

constitutes the fixed price area of the FPWS.

3.6.3.3. Area 3, the Other Negotiated Maintenance (i.e., AFTO Form 103 items that are

not in AMR), documents any maintenance to be completed during depot and not included

in the AMR brochure. This area is not part of the fixed price and is listed for revenue

tracking.

3.6.3.4. Area 4, the Scheduled Mods, Time Compliance Technical Orders (TCTO), and

Other Negotiated Maintenance, documents any other non-3400 funded work

accomplished (e.g., mods, TCTO, foreign military sales, etc.). This area is not part of the

fixed price and is listed for revenue tracking.

3.6.4. The FPWS is prepared using the AMR brochure for the respective weapon system by

tail or serial numbered aircraft or missile. The weapon system PM and the maintenance

group will coordinate on and agree to all changes between the initial and final FPWS. (T-3).

There are two FPWS:

3.6.4.1. The weapon system PM will develop and forward the initial FPWS to

AFMC/A4FR Workflow no later than 30 days prior to depot maintenance induction. (T-

1).

3.6.4.2. The PM will update the final FPWS with approved changes to include approved

OOC requests and provide to AFMC/A4FR Workflow. (T-3). This is a coordinated effort

between the weapon system PM and the ALC maintenance group and business office

after all work is completed.

3.6.5. Calculation of fixed price. Tasks performed during depot maintenance are a

predetermined series of common depot maintenance tasks and tail or serial numbered aircraft

or missile specific tasks for each aircraft, missile or Other Major End Items (OMEI)

undergoing depot-level maintenance. Fixed prices are developed for each MDS and are

comprised of three elements: basic, options, and O&A.

3.6.6. The basic element of a fixed price is the price charged for each like aircraft, missile, or

item undergoing PDM, regardless of condition, for a predetermined series of common depot

maintenance tasks. The basic charge is computed by multiplying the number of DPSH by the

occurrence factors and by the approved sales rates. The tasks and number of DPSH are

determined by the appropriate planning and workload activity and are directly traceable to

AMR tasks and hours. Generally, tasks with 100% occurrence factors are included in the

basic package. However, tasks with less than 100% occurrence factor are also included. The

percent occurrence factor is charged for each item undergoing PDM.

3.6.7. Options are those tasks which are not common to every induction. This element

allows the customer and the depot to determine each price according to the needs of the end

item. For example, a modification may not be required for all inductions. Likewise, all

aircraft may not require painting. By identifying such tasks as options and computing a price

for each, the customer is provided a shopping list and the depot is given a more finite AMR

work specification. In most cases, the price for each option is determined by multiplying the

task hours from AMR or TCTO by the rates. Note: Options are not the same as occurrence

tasks.

24 AFMAN63-143 18 DECEMBER 2020

3.6.8. As documented in AFMCI 21-118, Aircraft Maintenance Production/Compression

Report, O&A items of work are done to correct a critical or major deficiency and depots

must receive approval from the Project Administration Officer or the PM Representative. (T-

3). Each depot package includes a standard number of trended O&A hours. Unused O&A

hours can be moved from tail to tail as needed, but only between the same MDS, fiscal year

(FY), and Funds Holder.

3.6.9. Fixed price includes average AMR brochure earned hours for the basic depot

maintenance tasks, option tasks and O&A hours funded and billed at earned hours times the

stabilized sales rate. This is known as standard cost. If actual cost is above or below the fixed

price standard cost, the working capital fund earns the difference or takes a loss between the

actual and the fixed price.

3.6.10. Billing is for average AMR brochure earned hours times sales rate.

3.6.10.1. If excess funding has occurred due to the maintenance group and PM agreeing

to change the requirement, the PM must use the OOC process and return the excess funds

as soon as possible prior to the end of the FY with the estimate of the remaining work to

be done by the maintenance group on this year’s inductions carried into the next FY. (T-

1).

3.6.10.2. If the PM or maintenance group discovers an additional task or deficiency that

is beyond the accepted scope of traditional O&A, the PM shall request additional funding

before the funds expire at the end of the FY. (T-1).

3.6.10.3. If the PM or maintenance group identifies unforeseen tasks for prior year

inductions and current year funding is needed, it must be for O&A tasks which are not

covered by the line item(s) for the basic work under the contract.

3.6.10.4. Depot work that carries over from one FY to another requires an estimate of the

price of the work required to be carried over into the next FY. The depot provides the

estimate to the PM so that adequate current-FY funding can be provided. Funding on

open job order numbers (JONs) must be analyzed by the depot and PM to ensure

adequate funding for the current year work. (T-3). However, it is the acceptance and

obligation of funding documents such as the customer order numbers that determine the

funding actually available for carryover.

3.7. The AMR Process Overview.

3.7.1. Stage one involves defining new tasks and updating existing tasks. Stage two involves

building hours for new tasks and adjusting hours associated with existing tasks. Stage three

involves the validation of the hours for each active maintenance task to produce a validated

depot maintenance requirement by FY.

3.7.2. Task level aircraft and missile depot maintenance requirements are documented in

three areas: work specification, AMR trended and non-trended tasks, and engineering

requirements DEV PAC. Each has its own purpose and content and serves as subsets of the

overarching AMR process.

3.7.2.1. The work specification documents general information relating to specific

weapon system depot maintenance requirements.

AFMAN63-143 18 DECEMBER 2020 25

3.7.2.2. The AMR trended and non-trended tasks identify the depot maintenance task

requirements and hours required to maintain aircraft and missile systems in mission-

ready status.

3.7.2.3. The Engineering Requirements DEV PAC fully defines new and existing

scheduled depot maintenance task details, analysis, supportability elements and approval

prior to a task being added, deleted, or amended in the work specification.

3.8. AMR Process: Stage 1 – Define New Tasks and Update Existing Tasks.

3.8.1. The first stage begins with CAM sending a tasking correspondence to air logistics

complex (ALC) offices, program offices, MAJCOMs, maintenance groups Defense Logistics

Agency (DLA), and 448

th

Supply Chain Maintenance Wing (SCMW) for the current year on

or about 15 November each year. Exact beginning and completion dates are driven by the

start date for the LRDP.

3.8.2. Emerging requirements can occur at any time, but maintenance tasks are file

maintained in the work specification in accordance with the LRDP timeline. Requirements

are based on need and not on the availability of funds.

3.8.3. Work specifications are of prime importance in securing maintenance services under

the AF depot maintenance concept and are the most critical documents in maintenance

negotiations. Work specifications are developed and file maintained within the CAM IT

system of record. They are prepared for supporting organic workload agreements, contract

depot maintenance, and interservice agreements. The work specification documents

information relating to specific weapon systems including: general information, receipt of the

weapon system at the facility, work requirements, final processing of the weapon system, and

applicable technical orders and directives. Work specifications are not authoritative technical

manuals and are not used to perform depot-level maintenance.

3.8.4. Program engineers develop the depot maintenance technical requirements and provide

them to the work specification manager who is responsible for the overall preparation,

content, and coordination of the work specification. The work specification is file maintained

in the CAM IT system of record. The work specification manager incorporates changes to the

work specification identified during the DEV PAC review and forwards the work

specification to the SOR for the development of the DPSH.

3.8.5. The work specification manager will be updated and reviewed to ensure new or

changed tasks, as well as existing tasks, are adequately defined. (T-3). The work

specifications govern the scope of maintenance and state the depot maintenance required to

be performed on government equipment.

3.8.6. The annual review may be used by program engineers to address other initiatives

which may impact a weapon system’s technical inspection and maintenance practices.

3.8.6.1. Items procured under the Improved Item Replacement Program may necessitate

a change to the work specification if the items are to be replaced during PDM (ref AFI

23-101, Material Management Policy).

3.8.6.2. Any engineering issues affecting the maintenance of AF weapon systems that

may adversely or positively affect airworthiness of the systems should be discussed

during the annual review and the Engineering Requirements Review Process (ERRP).

26 AFMAN63-143 18 DECEMBER 2020

3.8.7. The lead command, PM, and the appropriate Funds Holder(s) collaborate on all new,

amended or deleted active depot maintenance tasks for the performance year.

3.8.8. Changes to the work specification are addressed in the build and adjust hours stage.

The lead command, PM, and appropriate Funds Holder(s) shall complete collaboration in the

CAM IT system of record no later than the first week in April. (T-1).

3.8.9. After completing collaboration, the work specification manager will certify and

publish the work specification in the CAM IT system of record by the first week in April. (T-

1).

3.9. AMR Process: Stage 2 – Build and Adjust Hours.

3.9.1. The PM will ensure all organic depot maintenance workloads are file maintained in

the CAM IT system of record by man-hour. (T-1).

3.9.2. DPSH and occurrence factors are developed for new scheduled maintenance tasks,

and are adjusted as needed. Man-hour data is shown in DPSH. New or changed scheduled

maintenance tasks identified during the work specification reviews are assigned DPSH labor

standards by maintenance planning units. Standards are based on approved data, group

timing, work sampling, technical estimates, or trend analysis, and maintained in a project

workload planning system. Where feasible, three years of data should be considered.

3.9.3. When a task applies to a MDS but is not active or recommended for deletion, the

DPSH are kept and the occurrence factor is set to 0.00.

3.9.4. The PM shall use occurrence factors on non-trended task. (T-3). If all aircraft or

missiles of the same MDS are to receive the task or have that task applied to them, then the

occurrence factor is 1.00. If only a percentage of the aircraft or missiles receive the task, then

the occurrence factor should reflect that percentage. For example, if 12 PDMs are scheduled

in a FY, but only 6 receives a particular task, then the occurrence factor is .50.

3.9.5. Trend analysis is be performed on all tasks with occurrence factors less than 100%

and tasks with unpredictable workload. Trend analysis is not performed on a once-through-

the-fleet or predictable task. The two main purposes of trend analysis are to recommend hour

changes to trended tasks and recommend changes to occurrence factors of trended tasks.

Neither purpose should be seen as automatic approval of projections or to usurp any of the

functions of the AMR review process. Any large growth in hours (i.e., plus or minus 20%

and/or 50 hours) using the recommended trend value is justified in the CAM IT system of

record to document the driver of the increase or decrease. Properly justified alternative trend

analysis methods may be used if approved during the review process. The following

subparagraphs contain rules to use during trend analysis:

3.9.5.1. The PM will utilize standard data for trend analysis comes from the PDM

scheduling system and includes the following five categories of information: MDS, serial

number, AMR work specification code, completion date, and standard hours. Use of

alternate data, such as engineering data from systems other than PDM scheduling system,

is acceptable if all five categories of information are used. The PM will document the use

of alternate data. (T-3).

3.9.5.2. Three years of historical or engineering data is the standard number of years to

use for trend analysis. More or fewer years can be used to accommodate small fleets or to

AFMAN63-143 18 DECEMBER 2020 27

compensate for changes in scope. The PM will document any deviation from the three-

year standard. (T-3).

3.9.5.3. If a strong upward trend (i.e., R-squared value greater than .75) is shown and

other factors have been ruled out, use the trend line value as the out year

recommendation. In this case, also check to see if the predicted cost to repair in the out

years is below 70% of the cost to replace. If the case can be made to replace rather than

repair, then the appropriate planning needs to be implemented to assure parts availability.

Be prepared to discuss the cause of the increasing trend. The task should be monitored to

see if the trend continues.

3.9.5.4. If a strong downward trend (i.e., R-Squared value greater than .75) is shown and

other factors have been ruled out, then the recommendation is to use the mean value for

the out year projection if the trend line is projected to be between the mean and lower

range mean (LRM), or to use the LRM if the projected trend is below the LRM. Be

prepared to discuss the cause of the downward trend. The task should be monitored to see

if trend continues.

3.9.5.5. If the trend is upward and the R-Squared value is between .3 and .75, then the

recommended out year projection is to use the upper range mean (URM).

3.9.5.6. If the trend is downward and the R-Squared value is between .3 and .75, then the

recommendation is to use the mean value for the out year projection.

3.9.5.7. If the trend is either up or down and the R-Squared value is between zero and .3,

then the data is assumed to be random in nature and the recommended out year projection

is to use the URM.

3.9.5.8. In the case where recommendations for the out years fall outside the upper or

LRM, it is up to the PM to provide sufficient explanation of the root causes to support the

mathematical findings and document cause(s) and finding(s).

3.9.5.9. The LRM should be used for all O&A tasks. If the LRM is not used, the PM

must provide sufficient documentation to explain the root causes and support the use of

another value. (T-3).

3.9.5.10. The PM shall document the rationale of any deviations from the recommended

hours based on the trending data or above business rules. (T-3).

3.9.6. The PM and ALC maintenance personnel review the draft DPSH and occurrence

factors, and then negotiate if necessary. Unsupportable scheduled maintenance tasks are also

reviewed to determine if actions can be taken to preclude delaying the task to a future year.

Supportability research is completed with the DEV PAC, and negotiations between the

collaborative review team decide the best implementation plan for a task including the FY.

This activity should be completed by 1 April.

3.9.7. All operations that are task-specific are identified to the appropriate task group.

3.10. Reviews. Requirement reviews are conducted during the August timeframe as directed by

AFMC/A4F or biannually for new, changed, or deleted requirements for future FYs as directed

by the Chief Engineer.

28 AFMAN63-143 18 DECEMBER 2020

3.10.1. The PM, or their designee, file maintains changes from the review meetings and

creates the baseline AMR brochure. Once changes from the review meeting have been file

maintained in the CAM IT system of record, the AMR brochure is considered baselined.

3.10.2. Scheduled maintenance tasks meeting the following criteria are identified and

reviewed by the team:

3.10.2.1. Any new tasks.

3.10.2.2. Once-through-the-fleet tasks.

3.10.2.3. Tasks that have changed by plus or minus 20% and/or plus or minus 50 hours.

3.10.2.4. Tasks with supportability issues that impact aircraft flow days or that will move

a task to a future year.

3.10.2.5. All tasks meeting the criteria established above will be reviewed and

coordinated with the MAJCOM POC(s) and PM via the CAM IT system of record. (T-3).

3.11. AMR Brochure.

3.11.1. The AMR brochure baseline is completed with the successful collaboration of the